HAMMER @formnext 2024! Visit us at Hall 11.0-A66

About Us

HAMMER is focused on design and Hi-Res complex devices manufacturing for both nuclear/astro-particle physics research and industrial technology transfer and services.

INFN Technology Transfer

The INFN is a leader organisation in basic research in the field of physics. To realise worldclass scientific experiments, researchers and technicians countinuosly develop cutting edge technologies in our specialised laboratories, always acquiring new expertise.

Technical Features

In the INFNs context, HAMMER poses itself as a network for AM prototyping, quality check and chemical analysis. Intense activities, often in collaboration with industries, are ongoing in this field. Download the know-how card

Our Services

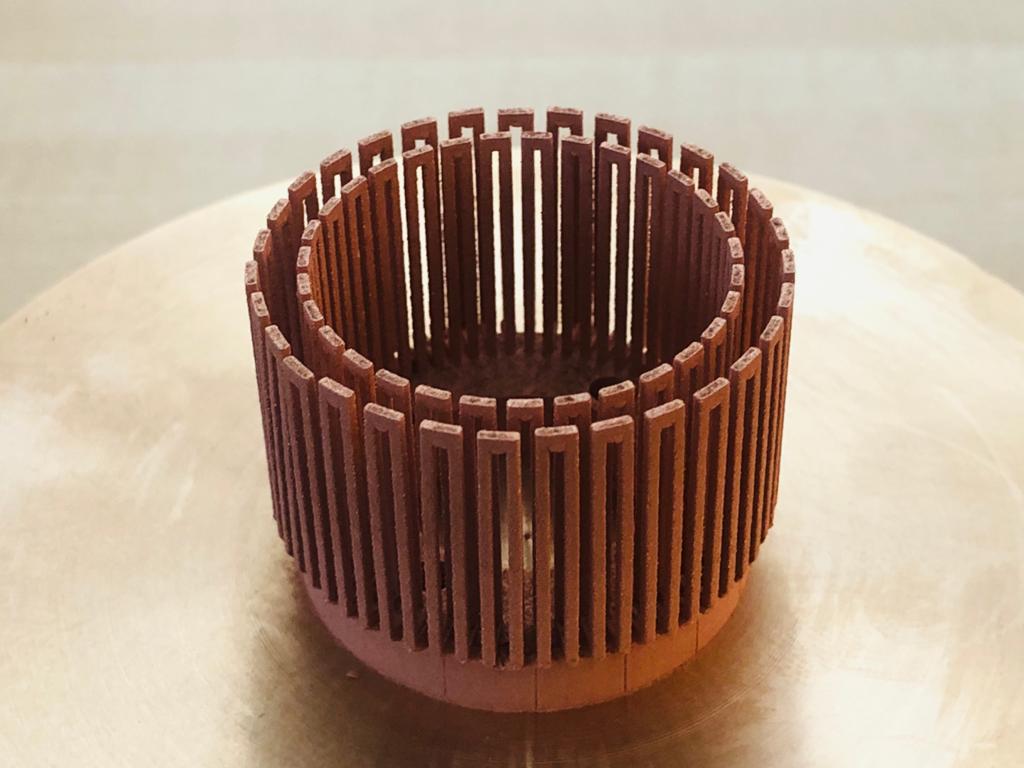

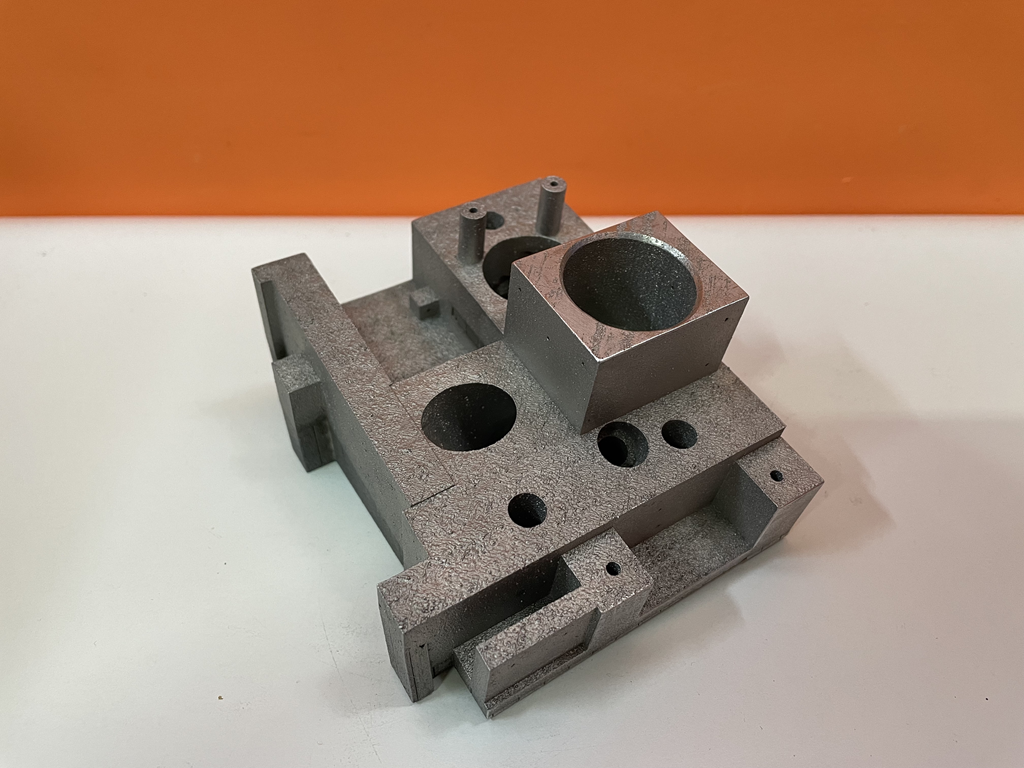

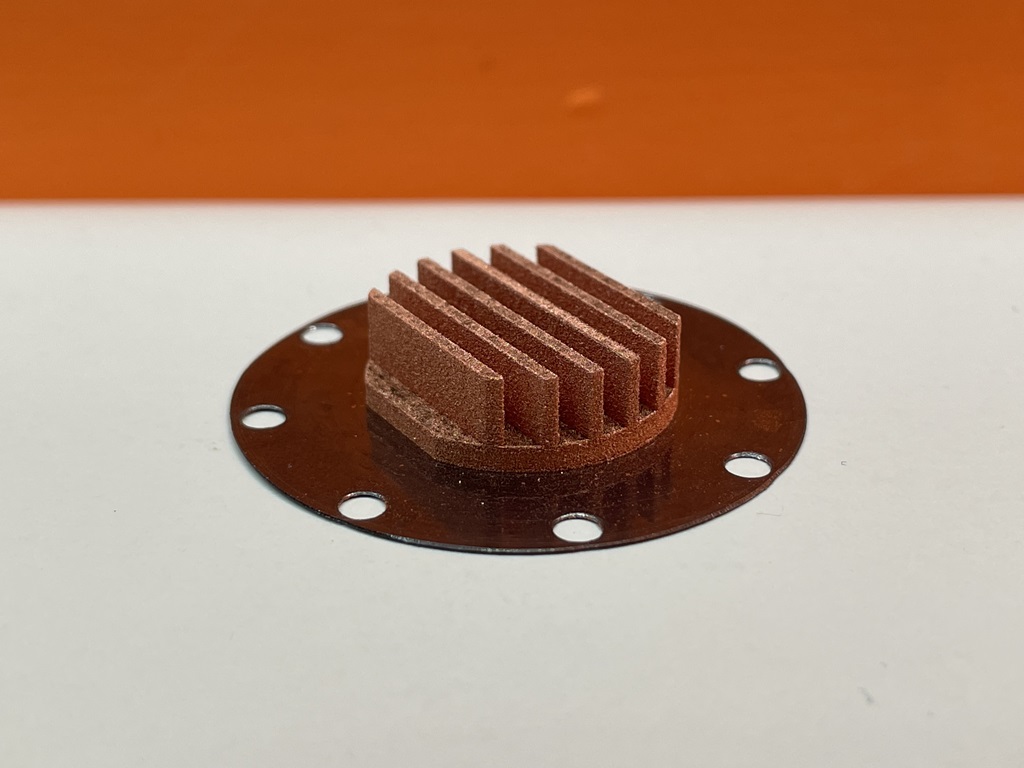

Hi-Res Manufacturing of plastic and metal components

Laser-Powder Bed Fusion (L-PBF), Stereolitografy (SLA), Digital Light Processing (DLP), Fused Deposition Modelling (FDM).

Heat Treatment

Heat Treatment on metals up to 1200 °C

Stereoscopic Hi-Res 3D scanning & Reverse Engineering

3D Stereoscopic Scanner (up to 0.07 mm of accuracy).

4K Ultra-High Accuracy Microscope and Automatic Profilometer

Material and production quality analysis

Material Testing

Tensile, bending and compression test at room, low (-150 °C) and high (+350 °C) temperature.

X-Ray Computer Tomography (coming soon…)

Material and Additive Manufacturing process characterization

Control of chemical composition of the processed materials

Spectrometric Characterization

Finite Element Simulations

L-PBF Process Simulation, Structural, Thermal and Fluid Dynamics Analysis.

NAMOR – Neutron Techniques for AM

Neutron Tomography, Diffraction, Brag-edge

https://namor.sites.lngs.infn.it/

Facilities

Gran Sasso National Laboratory (LNGS)Mechanics Service - Design & AM Dept.

Gran Sasso National Laboratory (LNGS)Mechanics Service - Design & AM Dept. Technologies

• L-PBF machine (x2), new L-PBF (coming soon)

(Cu, CuCrZr, GRCop-42, AISI 316L, 17-4PH, AlSi10Mg, Al-Sc, 16MnCr5, etc.)

• Stereolithography – SLA

• Digital Light Processing – DLP (x2)

• Fused Deposition Modeling – FDM (x2)

• Metal Powder Atomizer for L-PBF

• Heat Treatment Oven up to 1200 °C

• Filament Maker for FDM

• Spectrometric Characterization

• Powder granulometer (coming soon)

• Galvanic System

• 4K Ultra-High Accuracy Microscope

• 3D Stereoscopic Scanner (x2)

• Optical Profilometer

• Universal Testing Machine (-150 / +350°C)

• X-Ray Tomograph (coming soon)

• Simulation of L-PBF manufacturing process

Section of Rome (ROMA1)Mechanics Workshop

Section of Rome (ROMA1)Mechanics Workshop Technologies

• PoliJet

• Fused Deposition Modeling – FDM

Our Team

DONATO ORLANDI (LNGS)

Aerospace Engineer - Head of Mechanics Service

Stefano Nisi (LNGS)

Mechanical Engineer - Head of Chemistry Service

Matthias Laubenstein (LNGS)

Physics, PH.D. - HEAD OF SPECIAL TECHNOLOGY SERVICE

Alessandro Lalli (LNGS)

CAM / CAD Designer

Danilo Tatananni (LNGS)

ADDITIVE MANUFACTURING TECHNICIAN

CRISTINA GIANCARLI (LNGS)

Chemical Engineer

Francesco Ferella (LNGS)

Chemistry, Ph.D.

Angelo Corsi (LNGS)

MECHANICAL TECHNICIAN - Head of Mechanical Workshop

BRUNO ROMUALDI (LNGS)

MECHANICAL TECHNICIAN

SIMONE CIOCCOLINI (LNGS)

MECHANICAL TECHNICIAN

DAVIDE GIUSTI (LNGS)

MECHANICAL TECHNICIAN

Valerio Pettinacci (ROMA1)

Material Engineer - Head of Design Service

Ilaria Rago (ROMA1)

Nanotechnology Engineer, Ph.D.

Marco Iannone (ROMA1)

MECHANICAL TECHNICIAN

Ilaria Caravella (GSSI)

Mechanical Engineer

Matthias Junker (LNGS)

Physics, PH.D. - Head of Accelerator Service

Federico Ferraro (LNGS)

Physics, Ph.D. - Researcher